The word nonwoven means neither “woven” nor “knit”, but the fabric is much more. Non-woven is a textile structure which is directly produced from fibers by bonding or interlocking or both. It does not have any organized geometrical structure, rather it is the result of the relationship between one single fiber and another. The actual roots of nonwovens may not be clear but the term “nonwoven fabrics” was coined in 1942 and were produced in the United States.

Non-woven fabrics are made in 2 main methods: they are either felted or they are bonded. Felted non-woven fabric is produced by layering thin sheets, then applying heat, moisture & pressure to shrink & compress the fibers into a thick matted cloth which will not ravel or fray. Again there are 3 main methods of manufacturing bonded non-woven fabrics: Dry Laid, Wet Laid & Direct Spun. In Dry Laid Non-woven Fabric manufacturing process, a web of fibers is laid in a drum and hot air is injected to bond the fibers together. In Wet-Laid Non-woven Fabric manufacturing process, a web of fibers is mixed with a softening solvent which releases a glue-like substance that bonds the fibers together and then the web is laid out to dry. In Direct Spun Non-woven Fabric manufacturing process, the fibers are spun on to a conveyer belt and glues are sprayed on to the fibers, which are then pressed to bond. (In case of thermoplastic fibers, glue is not required.)

Nonwoven Products

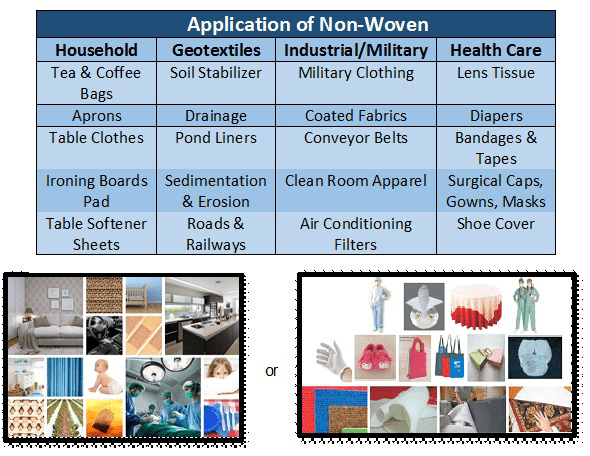

Wherever you are sitting or standing right now, just pay a look around and surly you will find at least one non-woven fabric. Nonwoven fabrics penetrate a wide range of markets including medical, apparel, automotive, filtration, construction, geotextiles and protective. Day by day the use of non-woven fabric is increasing and without them our present life would become so incomprehensible. Basically there are 2 types of nonwoven fabric: Durable & Disposal. Around 60% of nonwoven fabric are durable and rest 40% are disposal.

Few Innovation in Non-woven Industry:

Non-woven Industry is always being enriched with time demanding innovations and this also helps to advance the businesses.

Surfaceskins (Nonwovens Innovation & Research Institute- NIRI): It is antibacterial door pushing pads & pulling handles which are engineered to kill deposited germs & bacteria within the vital seconds, between one user and the next one passing through the door. Thus it helps to prevent the spreading of the germs and bacteria among the users.

Reicofil 5 (Reifenhäuser Reicofil GmbH & Co. KG): This technology delivers the most productive, reliable and efficient line technology which reduces hard pieces by 90 percent; increases output up to 1200 m/min; streamlines maintenance time; reduces energy consumption.

Remodelling™ Compound Hernia Patch (Shanghai Pine & Power Biotech) : It is an electro-spun nano-scale patch which is very cost-effective absorbable biological graft and serves as a growth medium for new cells, ultimately biodegrading ; reducing the rate of post-operative complications.

Global Demand:

Maintaining almost an unbroken period of growth over the past 50 years, nonwoven can be the sunrise segment of the global textile industry with higher profit margin than any other textile products. Global market of non-woven fabric is led by China with a market share of around 35%, followed by Europe with a market share of around 25%. Leading players in this industry are AVINTIV, Freudenberg, DuPont and Ahlstrom, where AVINTIV is the largest manufacturer, with the production market share of around 7%.

In recent time, with the rise of COVIC-19 cases, demand for hygiene & medical products made of non-woven fabric (such as: surgical caps, surgical masks, PPE, medical apron, shoe covers etc) has increased up to 10x to 30x in different countries.

According a report of world largest market research store “Research & Markets”, Global Nonwoven Fabrics market accounted for $44.37 billion in 2017 and is expected to reach $98.78 billion by 2026, growing at a CAGR of 9.3% during the forecast period. It is also assumed that the durable non-woven market will grow with a higher CAGR rate.

Why Non-Woven?

Nonwovens are innovative, creative, versatile, high technology, adaptable, essential and decomposable. This type of fabric is directly produced from fibers. So there is no need of yarn preparation steps. The manufacturing process is short & easy. Where to produce 5,00,000 meters of woven fabric, it takes around 6 months (2 month for yarn preparation, 3 months for weaving on 50 looms, 1 month for finishing & inspection), it takes only 2 months to produce the same quantity of non-woven fabric. Therefore, where the production rate of woven fabric is 1 mete/minute and the production rate of knit fabric is 2 meter/minute, but the production rate of non-woven fabric is 100 meter/minute. Moreover production cost is low. Besides, nonwoven fabric exhibiting specific properties such as higher strength, breathability, absorbency, durability, light weight, retard flames, disposability etc. Because of all these phenomenal features, textile sector is moving towards non-woven fabrics.

Conclusion:

Non-woven fabric is often said to be the future of textile industry as their global demand & versatility are only getting higher & higher.

Post time: Mar-16-2021