When it comes to wiping a surface – whether it’s a counter or machine part – there’s a perception that using a rag or shop towel multiple times is less wasteful than using a disposable wipe.

But rags and towels sometimes leave behind lint, dirt and debris, using them can compromise a manufacturing process and those contaminants can potentially get into the product being manufactured, resulting in rework.

Here are some other reasons why rags and laundered shop towels are not as dependable as industrial wipes:

Rags

Are inconsistent in size, shape and material

May contain pins, buttons and metal shavings which can lead to scratches and other imperfections on surfaces

Occupy more storage space in industrial warehouses than disposable wipes

Laundered Shop Towels

Can retain lead, a toxic heavy metal, which can cause serious health issues to the worker like elevated blood lead levels and hypertension

Not engineered for specific applications

Contribute to landfill waste

Disposable Wipes Are More Efficient Than You Think

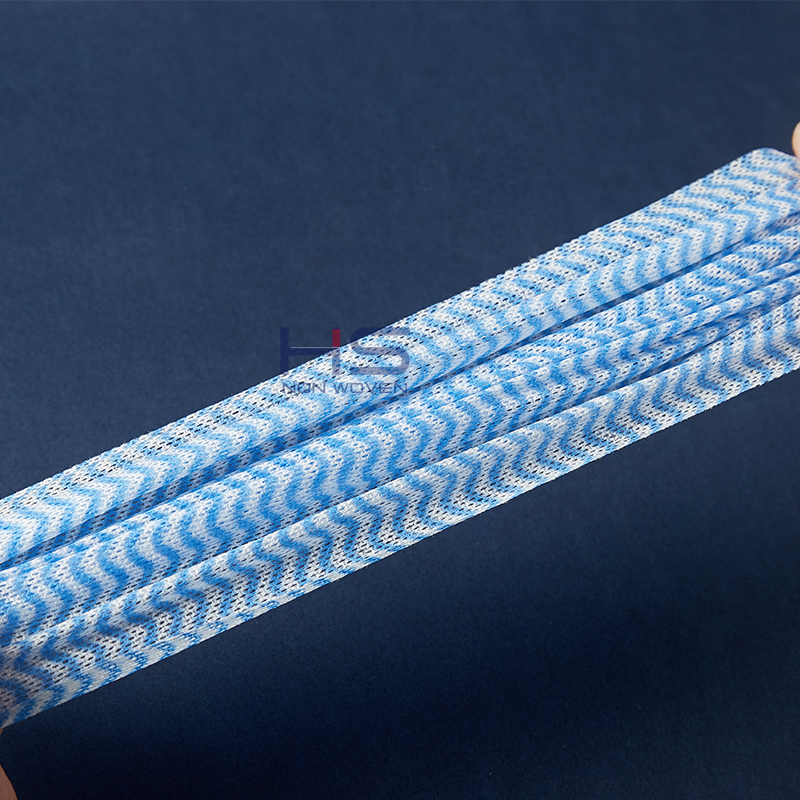

Disposable wipes like HS Wipes are absorbent, making it quick to clean a piece of equipment and can reduce machine stoppages.

When choosers use the right tools, they will ultimately see that they can impact quality, delivery and costs in a much bigger way than they could have imagined.

HS industrial wipes are tough, durable and absorbent! Suited to the varied needs of manufacturing and industrial applications. Whether it is mining engineering,printing or painting

lf you're looking for an alternative to rags. industrial wipes offer many benefits. For instance, industrial wipes are more consistent in size. weight and absorbency than raas. This increases productivitv and reduces wastage. And they’re more hvaienic.less bulky and cheaper to transport and store.

Post time: Sep-23-2022